Water Pressure

(bar) |

Orifice/hole(mm2) |

Water capacity

(l/sek) |

Water capacity

(l/month) |

Water capacity

(m3/month)

|

Water capacity

(m3/year) |

|

5 |

0,5 |

0,006 |

0,36 |

15,8 |

189 |

|

1,0 |

0,016 |

0,96 |

42,0 |

504 |

|

5,0 |

0,372 |

22,32 |

977,1 |

11 725 |

|

10,0 |

1,406 |

84,36 |

3 692,9 |

44 315 |

|

10 |

0,5 |

0,008 |

0,48 |

21,0 |

252 |

|

1,0 |

0,023 |

1,38 |

60,4 |

725 |

|

5,0 |

0,497 |

29,82 |

1 305,4 |

15 665 |

|

10,0 |

1,989 |

119,34 |

5 224,2 |

62 691 |

|

16 |

0,5 |

0,010 |

0,60 |

26,3 |

315 |

|

1,0 |

0,029 |

1,74 |

76,2 |

914 |

|

5,0 |

0,629 |

37,74 |

1 652,1 |

19 825 |

|

10,0 |

2,515 |

150,90 |

6 605,8 |

79 270 |

LOCATION OF WATER LEAKAGES FROM METAL AND NON-METAL WATER SUPPLY

NETWORKS

Leaks in pipelines: metal, plastic,

asbestos or concrete are located in pipes filled with water under

pressure of at least 2 bar (0.2 MPa = 2at).

A diagram or sketch of the water supply and sewage system must be

submitted for review.

Research techniques used.

Research techniques used.

The following activities are used to locate hard-to-detect water leaks:

Listening with a rod microphone for available elements of the water

pipeline

There is needed access to:

water supply wells, hydrants, earth gates, etc..

In special cases, rooms should be made available in buildings where the

water supply connection to the building is visible.

Attention:

- Prior excavation by the service provider is necessary, as far as

possible

possibilities, any buried water supply wells, gate valve boxes

earthworks, etc..

Current practice in the field of pipeline testing performed by

The Wodoserwis company shows that instead of locating water leaks

on networks, time is unnecessarily used for localization

and unearthing wells or earth gate boxes lost in the field

waterworks.

Correlation (location) of

pipeline leaks using a correlator and microphones (accelerometers) or

hydrophones.

Correlation for metal or non-metal pipelines.

Equipment used:

Microphones/accelerometers

If the length of the tested non-metallic pipeline (or cast iron) exceeds

100 – 120 meters and there are no available elements

water pipeline along this length. The person ordering the service is obliged

to make open pits of the pipeline every 30 ÷ 100 meters in order to

installation of steel clamps for the pipeline by Wodoserwis.

Clamps allow you to attach sensors/accelerometers to a non-metallic

pipeline.

Note: If the non-metal pipeline is equipped with hydrants, it is not

necessary to perform the above-mentioned work. excava tions.

tions.

Hydrophones

Hydrophones are screwed to the "external" or "internal" hydrant sockets or

to other available intake valves (if there are no hydrants) to which

you can tighten the hydrophones.

An employee operating the water supply network, authorized to unseal and

open ground or above-ground hydrants, is required,

to which the hydrophones will be screwed.

In addition to the hydrant wrench, you need a key for the hydrant shut-off

valve.

Correlation of pipeline

leak locations using a correlator and multisensors (acoustic recorders),

optional method.

The multisensors are equipped with very sensitive piezoelectric microphones

with an amplifier, data memory, a battery and a radio module with an

antenna.

Depending on the environmental conditions, multi-sensors are left on the

pipelines at night.

Multisensors are used optionally, as needed.

It is possible to perform correlation measurements on pipelines equipped

with steel or cast iron elements located at very great depths.

Listening to the ground above the pipeline with a geophone (and possible

sound analysis with specialized software).

Auscultation with a geophone of the surface above the pipeline with a

confirmed, probable leak location in order to precisely locate the leak.

Quick physicochemical analysis of water to immediately recognize the type of

water

- when locating places of water leaks, depending on the needs, water

occurring in the field, in the area of the pipeline, is collected and

analyzed

(sewerage, ditch, ground surface, tunnel, etc.).

The quality of water taken from the area is compared with water from the

tested pipeline.

For water supply companies interested in the issue of searching for water

leaks from pipelines, the Company has developed a several-page GUIDE, .PDF

format, entitled: "Problems of reducing water losses in water supply

networks" - available for download on the Company's website.

Problemy

ograniczania strat wody w sieciach wodociągowych - Poradnik ,

format .PDF .

MONITORING OF WATERWORKS

The company offers monitoring of

the water supply network.

Measurements of water flows and pressure in pipelines, measurements of water

levels.

Solutions in the system of wired and wireless transmission/registration of

energy media network parameters to the computer of the unit on duty.

Advantages of monitoring:

- reducing water losses in the water supply network by quickly locating

leaks

- improving the functioning of supervision over the water supply network

- improving process control

- reducing and automating the operation of networks and technological

facilities

- improving the safety and reliability of devices

Registration of water flows with a programmable recorder for connection to

flow meters and transmitters (2 inputs 0/4-20 mA, 2 PULS inputs), ability to

display up to 4 measurement channels.

- Simultaneous recording of additional other parameters of the water supply

system (e.g. pressure, level)

- Instantaneous flow rate readings

- Determining extremes (minimum and maximum threshold values)

- Flowmeter operating time counter

- Archiving results on a computer using a card and specialized software

- Data averaging

- Graphical and tabular presentation of results

- Print reports

The new

a data logger specially designed for the needs of water

suppliers. The logger is battery powered which lasts for 5 years

even with integrated GSM/GPRS module. This unit is available in

several configurations with internal sensors and various input

channels.

Wireless

programming and read out:

Yesterday was the time to connect each logger with a cable to

program or to read data. In combination with the PC radio

interface USB-E-box one can simply program several loggers one by

one via radio. The read out process works the same if you use the

Reader Box. Simply go near by the logger (radio range up to

20m and more) and collect all data stored in the internal memory of

the logger. Transfer the data later to your PC and do your

analysis.

Recording:

How ever

your recording interval should be: you simply program the loggers

for your special needs. From 1 sec. up to 31 days an interval can be

chosen. The huge internal memory of the logger saves data up to 28

years and if this is not enough one can simply upgrade the memory

with standard SD/MMC cards.

Sensors:

This unit is available with integrated pressure sensors or

simply as a “regular” data logger. All 0-5V or 0-20 mA sensors can be

attached and the data can be logged. The accuracy is certainly

± 0.1%.

Telemetry data logger:

As a special version the device comes with an integrated

quad-band GSM/GPRS modem to transmit data over a long distance.

Data are provided via FTP to easily integrate the data into

existing telemetry systems.

Alarming:

Each channel has individual alarm thresholds. Once this threshold is

reached the logger sends a SMS or message to the telemetry

system.

LOCATION OF WATER AND SEWAGE UTILITIES

ROUTING - LOCATION OF PIPELINES

Metal pipelines

- Detection of network routes and connections up to a depth of 6 m.

- Determining the depth of installation of pipelines in the ground.

To locate metal pipes (steel, cast iron), a locating kit equipped with a

pulse generator is used - connected to

available pipeline element.

Each time, the maximum pipeline routing range is up to 150 meters in both

directions from the access point, i.e. 2 x 150 meters = 300

meters.

If there are no available pipeline elements, it is possible to locate the

pipeline using another method without measuring the depth of the metal

pipeline foundation.

Non-metallic pipelines made

of:

- plastics

- concrete, asbestos, cast iron

To locate the route of pipelines filled with water, Wodoserwis uses its own,

innovative technical solution

on generating small water hammers (smaller or larger - depending on needs)

in the tested pipeline and listening to the ground,

thus identifying the pipeline route.

A connection to the pipeline via a hydrant or a building tap is used here.

When creating shocks, water is thrown into the area or into the sewage

system.

If a hydrant is used, the service ordering party must provide a person

authorized to open hydrants.

In the case of an earth hydrant, an appropriate hydrant stand must be

prepared.

Each time, the maximum routing range of the tested pipeline is approximately

100 meters on both sides of the pipeline from the production site.

water hammer, i.e. up to approximately 200 meters of the routed pipeline.

Attention:

it is possible to locate plastic pipelines if the pipeline was laid with

a metal tape or signaling cable for the purpose of later locating the

pipelines using

locator cooperating with the signal generator.

LOCATION OF METAL: MANHOLE COVERS, GATE

BOXES, HYDRANT BOXES, VALVE STYLES, etc.

The devices used by Wodoserwis enable the

location of metal (steel, cast iron) elements of water and sewage

infrastructure - fittings, manhole covers,

gate valve stems to a depth of 2.5 meters.

If instead of a metal cover, a reinforced concrete cover was placed on

the well manhole, the locator will detect the reinforcement of this

cover.

A buried water or sewer well that is located at the junction of a metal

water or sewer main will be located

to a depth of 6 meters by locating water supply or sewage network

routes.

If the earth gate valve box is lost in the field, it is possible to

locate the gate valve stem, even if the stem diameter is only 10 ÷ 15

mm.

Inspection of hard-to-reach places with a

micro-inspection camera

- lens housing diameter: 17 mm

- monitor diagonal: 52 mm

- cable length: up to 6.5 m

- intended use: pipes, tunnels, mini windows with a diagonal of up to 50

- 80 mm

- the camera can work underwater up to a depth of 3.0 m

Photos Gallery

return up ↑

WATER CONSUMPTION STANDARDS

In Poland water consumption

standards are regulated by the "Regulation of the Minister of Infrastructure

of January 14, 2002 on determining average water consumption standards"

(Journal of Laws No. 8 of January 31, 2002 - Item 70):

The recommended standards

for water consumption in Poland

Normy zużycia

wody reguluje "Rozporządzenie Ministra

Infrastruktury z dnia 14 stycznia 2002 r. w sprawie określenia przeciętnych norm zużycia wody"

(Dziennik Ustaw nr 8 z dnia 31 stycznia 2002 r. - Poz. 70)

The regulation contains average water

consumption standards for the following groups of recipients:

Household

Watering home gardens and agricultural crops

Services, Farms and livestock facilities

Servicing motor vehicles, agricultural machinery and workshops

Agricultural and food processing plants

Works

Chemical plant protection

Military facilities of the ministries of defense and interior affairs

However, there are another detailed recommended standard the water

consumptions based on technical documentary or operator’s

manual etc. as given below.

Other detailed, individual water

consumption/demand are resulting from technical documentation or

technology.

|

|

|

.

Another detailed standards water consumption

Air Conditioning

Air Conditioner type KT 2.1

Condenser cooled water temperature: 12 o C, water capacity: 400 l/h, inside

diameter d= 15 mm.

(based on air conditioner KT 2.1 documentary – Germany, VEB Maschinen und

Apparatebau Schkeuditz)

Another type KT:

KT 4: 350 l/h

KT 4.1: 420 l/h

Type CAS (Clivet - Italy), ex: CAS 51: 1 800

l/h

Type K 3 300: 200 l/h

Laboratories

The water consumption in laboratories (data based on installation

documentary):

a

polish water re-distiller type REL 5 (capacity 5 l/h) - consumption

150 l/h

a

polish water distiller type DEM 10 (capacity 10 l/h) - consumption

85 l/h, type DEM 5 (capacity 5 l/h) - consumption 42 l/h

Bakeries

The water intake only for dough production (the water intake as a raw

material without sewage for sewage system)

1. The dough production:

100 kgs flour needs 50 l water, it means that 1 kg the flour needs 0,5 l water

2. Steam production in baking oven:

Medium size baking oven needs 870 l water per day

3. Water consumption for steam in steam pot:

1 steam pot needs 1 000 ls the water per month

(Information comes from bakery’s owner in Krakow city consuming 98 600 kilograms

of flour a month. Eight tenth of this flour is used for bread and the rest for

sweet croissants and doughnuts).

According to “Rozporzadzenie Ministra Infrastruktury z dnia 14 stycznia 2002 r.

w sprawie okreslenia przecietnych norm zuzycia wody (Dziennik Ustaw nr 8 z dnia

31 stycznia 2002 r. - Poz. 70)”, all in all the bakery needs: 2,0 m3 the water

for 1000 kg bread, it means that 1 kg bread needs 2 l the water.

Canteens

(based on

the Polish book: "Wyposazenie stolowek w zakladach przemyslowych" -

author: Z. Mirski) (based on

the Polish book: "Wyposazenie stolowek w zakladach przemyslowych" -

author: Z. Mirski)

the water for handy dishes washing: 7,5 l for 1 meal

the water for dinner: 30 l/dinner (the first course and main course altogether)

the water for worker regenerative meal: at the table - 15 l/meal, take away meal

- 7,5 l/meal.

Hydrants

Outdoor hydrants

In the fire-fighting water supply network, mainly external above-ground

hydrants with a nominal diameter of DN 80 are used.

The nominal capacity of an external fire hydrant at a nominal pressure

of 0.2 MPa (2 bar) measured in the hydrant valve during water intake for

a DN 80 hydrant should be at least 10 dm3/s.

Regulation of the Minister of Internal Affairs and Administration of

July 24, 2009 on fire-fighting water supply and fire routes (Journal of

Laws No. 124 - Item 1030).

In the Regulation, at least:

- Types of facilities requiring fire protection water supply for

external fire extinguishing

- Methods of determining the required amount of water for fire

protection purposes

- Fire protection requirements for water supply networks

- Fire pumping stations

- 4 tables regarding the required amounts of water for fire protection

purposes for settlement units and facilities

Internal hydrants

Regulation of the Minister of Internal Affairs and Administration of

June 7, 2010 on fire protection of buildings, other structures and areas

(Journal of Laws No. 109 - Item 719).

Minimum water intake efficiency measured at the nozzle outlet:

for hydrant 25 - 1.0 dm3/s

for hydrant 33 - 1.5 dm3/s

for hydrant 52 - 2.5 dm3/s

for valve 52 - 2.5 dm3/s

In the Regulation, at least:

- maximum working pressures in the fire-fighting water supply system

- number of simultaneously operating hydrants

- capacity of fire protection tanks

- nominal diameters of power cables

Car dismantling stations

Car

washing: Car

washing:

- passenger: 150 l/1 washing (according to the above-mentioned

"Regulation")

- delivery van: 500 l/1 washing (according to the above-mentioned

"Regulation")

Water demand to keep streets and squares clean:

- for effective one-time mechanical washing of streets and squares: 2

l/m2 of improved surface.

Basis: "Guidelines for programming water demand and the amount of sewage

in urban settlement units" - Ministry of Administration, Land Management

and Environmental Protection. Department of Public Utilities. Institute

of Environmental Management - 1978

At one of the car scrapping stations in Krakow with:

- parking lot for 20 parking spaces with an area of 350 m2

- a scrap yard with an area of 330 m2

water consumption is from 15 to 23 m3/month

Vehicles

cleaning the water and sewage system Vehicles

cleaning the water and sewage system

- without water recovery systems

Manufacturers' names, capacities of high-pressure pumps:

1. Dobrowolski 265 or 315 dm3/min

2. Else 291 - 942 dm3/min

3. HAKO Polska 120 dm3/min

4. INTEGRA 90 - 500 dm3/min

5. Interglobal 470 dm3/min

6. KANRO 70 - 210 dm3/min

7. MWM Brzesko 90 -500 dm3/min

8. REMO FPHU up to 500 dm3/min

9. UNIMARK 40 - 500 dm3/min

10. WUKO 216 - 406 dm3/min

Basis: Data from the magazine Wodociągi i Kanalizacja 9/2011 (article:

"Report - operating equipment of water and sewage networks")

With:

- parking lot for 20 parking spaces with an area of 350 m2

- a scrap yard with an area of 330 m2

water consumption is from 15 to 23 m3/month

front page

←

return up ↑ |

PIPELINE TIGHTNESS TESTING REGULATIONS

Pipeline tightness testing

regulations (as of 2006)

How to perform a pipeline/installation leak

test

- tightness test

General technical conditions for the execution and acceptance of

water supply networks and water supply installations - technical

requirements, developed on the basis of applicable regulations by the

Central Research and Development Center for Installation Technology

INSTAL (COBRTI INSTAL) - volume 3, volume 7, recommended for use by the

Ministry of Infrastructure.

Comments:

The test should be performed before

covering the installation; if it is required to cover part of the

installation, separate tests should be carried out as part of partial

acceptance tests.

A pressure gauge with a reading accuracy

of 0.1 bar should be connected to the installation.

The test procedure is different for metal

pipes and plastic pipes.

In the case of plastic pipes, the

procedure is longer and more complicated due to the fact that the

pressure drop recorded on the manometer does not have to be the result

of leaks, but results from

initially due to the flexibility of the cables.

The examination is divided into preliminary and main examination

(conducted immediately after a positively completed preliminary

examination).

The preliminary test consists in increasing the pressure to the test

pressure three times every 10 minutes, and then observing the

installation.

for ˝ hour

The test is considered successful if there are no leaks or condensation,

especially at the connections, and the pressure drop is less than 0.6

bar.

The main test consists of raising the pressure again to the test

pressure and observing the installation for 2 hours. The test is passed

if there are no leaks

and dew, and the pressure drop is not greater than 0.2 bar.

Therefore, in the case of plastic installations, the pressure gauge

readings are an auxiliary element and significant pressure drops are

allowed.

To properly check the installation, it is necessary to observe the

connections to see if they show any leaks.

The air test pressure should not exceed 3 bar.

Installers sometimes, by mistake, use the pressure as for the water

test, i.e. most often 6 bar for central heating installations and 10 bar

for water supply installations.

After the test, a test report should be prepared specifying the test

pressure and test results.

COBRTI INSTAL notebooks provide a template of the Leak Test Protocol.

Recipes according to COBRTI INSTAL:

Water networks:

1. The test pressure in the networks should be 1.5 times the working

pressure, but not less than 1 MPa (10 bar).

2. The tightness of the pipe should ensure that the test pressure is

maintained for a period of 30 minutes during the hydraulic test.

Water installations:

Leak test should be carried out with water. During partial acceptance of

installations, in justified cases, it is allowed to perform a tightness

test using compressed air.

Water tightness test

1. The test pressure in the networks should be 1.5 times the working

pressure, but not less than 1 MPa (10 bar). The test pressure is

the pressure at the lowest point of the installation at which the test

is carried out testing its tightness.

2. Cold water tightness testing of metal water supply installations

consists of a main test (the pressure cannot drop by more than 2% for 30

minutes), and in the case of plastic pipes

artificial from the preliminary and main tests (the pressure must not

drop more than 0.2 bar for 2 hours).

Air tightness test

1. The pressure value for testing the tightness of the installation with

compressed air should not exceed 3 bar.

2. The condition for recognizing the test results as positive is that

there is no leakage in the installation and the manometer does not show

a pressure drop.

Note: issue no. 6 COBRTI

INSTAL concerns the technical conditions for the execution and

acceptance of heating installations

In the case of a central heating installation, the test pressure should

be 2 bar + working pressure at the lowest point of the installation, but

not less than 4 bar for a radiator installation and 9 bar for a surface

installation, i.e. floor or wall.

This is due to the fact that pumps with a higher lifting height are used

in underfloor heating due to much higher flow resistance in the

installation.

Tightness testing of a water pipeline

or water installation - acceptance tests according to the following

standards:

Waterworks - External pipes

1. "Requirements and tests": PN-B-10725:1997

2. "Water supply - Requirements for external systems and their

components": PN-EN 805: 2002, PN-EN 805: 2002/Ap1

It is recommended that the test procedure be determined by the designer.

The procedure should include three stages: preliminary test, pressure

drop test, main pressure test: water loss method or pressure loss

method.

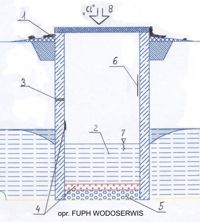

Tightness testing of water tanks -

acceptance tests according to the following standards

Waterworks and sewage

- "Tanks. Requirements and tests": PN-B-10702:1999

- "Water supply - Requirements for systems and their components intended

for storing water": PN-EN 1508: 2002

- "Unpressurized tanks. Requirement: PNs and tests"-B-73001:1996

- "Pressure tanks. Requirements and tests": PN-B-73002:1996

Sewerage tightness testing - acceptance

tests according to the standard:

- "Construction and testing of sewage pipes": PN-EN 1610: 2002, PN-EN

1610: 2002/Ap1

For

services operating water supply systems, Wodoserwis suggests the

following method of testing the tightness of the pipeline without a

pressure test.

For

services operating water supply systems, Wodoserwis suggests the

following method of testing the tightness of the pipeline without a

pressure test.

Thanks to a specially made reduction, it is possible to install an

accurate, high-class DN15 control water meter on

connections/installations regardless of the diameter of the existing

water meter and the type of connection between the flow meter and the

pipe.

For flange connections, the minimum length of the measuring system:

control water meter + reduction with flanges is 180 mm - 190 mm, which

allows for trouble-free installation of a flow meter in place of a water

meter, e.g. with a diameter of 50 mm (with an installation length of 200

mm).

front page

←

return up ↑

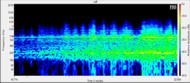

VIBROACUSTICS

Measurements of machine vibrations and

material noise, FFT spectrum

Measurements of machine vibrations and

material noise, FFT spectrum

Vibration measurements

Amplitude units:

- acceleration: g, m/s2

- speed mm/s

- offset: mm

Low frequency range: 10 Hz - 1,000 Hz (determining e.g. general machine

condition)

High frequency range: 4,000 Hz - 20,000 Hz (determining bearing condition)

Example applications:

- diagnostics of operating devices (including bearings: pumps, engines,

etc.) and early detection of their dysfunctions using a patented

measuring instrument algorithm for high-frequency measurements.

Assessment of the level of significance for engines, cooling towers, fans,

cooling tower drives, centrifugal pumps, positive displacement pumps,

air compressors, blowers, gears and spindles.

Fast response in the initial stage of failure in the noise phase, before the

appearance of the vibration and thermal phase of pump elements

and engines, allows you to protect the device from the need to replace the

main components of the device.

Early detection of damage significantly reduces repair costs and production

interruptions.

Early detection of damage significantly reduces repair costs and production

interruptions.

Three types of measurements: bearing vibration, total vibration and

temperature.

- pipeline vibration measurements, requirements according to manufacturers

of precision devices and measuring systems:

Flowmeters:

- differential pressure transducers (admissible values: frequency level

10-60 Hz, vibration ampl. 0.21 mm/60-2,000 Hz, acceleration ampl. 3g)

- Annubar averaging tubes (admissible values: frequency level 10-1,000 Hz,

vibration amplitude 0.15 mm, acceleration amplitude 2g)

Blood pressure monitors/thermometers:

- pressure/level/temperature transmitters (examples of permissible vibration

values: 4g, (10 - 2,000 Hz)

- protection analyses.

Example applications:

- measurements of pipeline sound emissions caused by high flow, no flow or

other factor

- noise measurements of machines and vibroacoustic devices, industrial

equipment, building infrastructure

Structure-borne noise measurements

Measurements with a piezoelectric microphone in a wide range of frequency

levels /Hz/.

FFT spectrum recordings of sounds

Pipes and machines vibrations - analysis

Vibration Meter

Sensitivity: 100 mV / g ±10 %

Measurement Range: 0.01 g to 50 g

Frequency Range:10 Hz to 1 000 Hz and 4 000 Hz to 20 000 Hz

Resolution: 0.01 g

Accuracy: at 100 Hz: ±5 % of measured value

Amplitude

Units:

Acceleration: g, m/sec2

Velocity: in/sec, mm/sec

Displacement: mils, µm

Quick Measurement

Overall Vibration (Low Frequency) Measurement with Severity Scale

Crest Factor+ (High Frequency Measurement in bearings)

Interpret Results:

Trending

Vibration Severity - ISO 10816-1

Data transfer

between the Meter and PC. Export Meter

data to an MS Excel spreadsheet

Range of activities:

Range of activities: Network routes are detected up to a depth of 6.0 m.

Network routes are detected up to a depth of 6.0 m.

Vibration and material noise measurements, FFT spectrum images of

sounds.

Vibration and material noise measurements, FFT spectrum images of

sounds. Company history: the beginnings of the business date back to 1992,

when it specialized in, among others, in the sale of self-closing

sanitary fittings and industrial nozzles for splashing and spraying

liquids.

Company history: the beginnings of the business date back to 1992,

when it specialized in, among others, in the sale of self-closing

sanitary fittings and industrial nozzles for splashing and spraying

liquids. tions.

tions.

(based on

the Polish book: "Wyposazenie stolowek w zakladach przemyslowych" -

author: Z. Mirski)

(based on

the Polish book: "Wyposazenie stolowek w zakladach przemyslowych" -

author: Z. Mirski)

Car

washing:

Car

washing: Vehicles

cleaning the water and sewage system

Vehicles

cleaning the water and sewage system

For

services operating water supply systems, Wodoserwis suggests the

following method of testing the tightness of the pipeline without a

pressure test.

For

services operating water supply systems, Wodoserwis suggests the

following method of testing the tightness of the pipeline without a

pressure test. Early detection of damage significantly reduces repair costs and production

interruptions.

Early detection of damage significantly reduces repair costs and production

interruptions.